IQC- Incoming Quality Control

We Screen the supply chain strictly, stable cooperative suppliers provide us with material, each components are sampled on each batches, ensure components meet the product requirements and prevent batch quality defects in advance.

Raw material inspectionCheck the color material without any impurities and, check the features meet the requirements of the order.

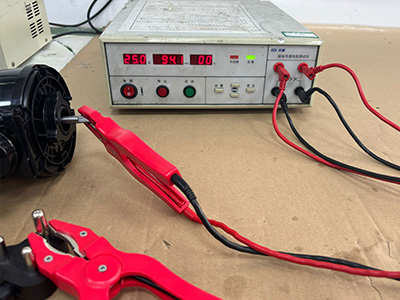

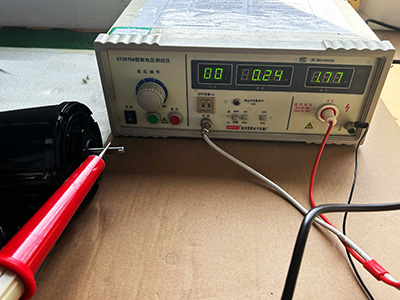

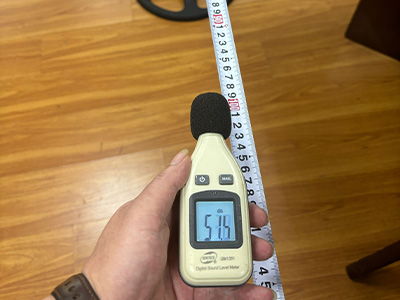

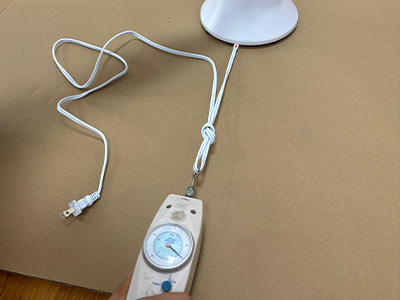

Accessory inspectionCheck the appearance, parameter and craftsmanship of the accessories which can meet the standards, randomly check the accessories can be installed normally.

Package inspectionCheck the thickness and printing pattern of box, the integrity of silkscreen and label.